A) Valve stem modifications:-

We successfully designed a push-type and collet-type design to overcome the major disadvantage of threaded vent tube by modifying existing valves.

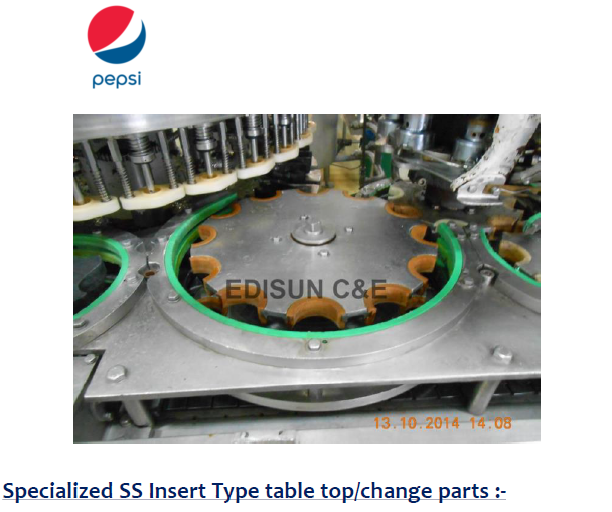

B) Specialized SS Insert Type tabletop/change parts :-

It is precisely designed to replace only UHMWPE (Green Strip) of guides & Nylon spider (starwheel) pockets for the spider to attain an entire new tabletop.

Results in extremely low Recurring cost.

C) LEVEL FILLING JUICE VALVE :-

Level filling juice valve fitted in the existing machine.

With this bottom closing filling valve, we minimized the syrup loss and overcame the problem associated with brimful filling.

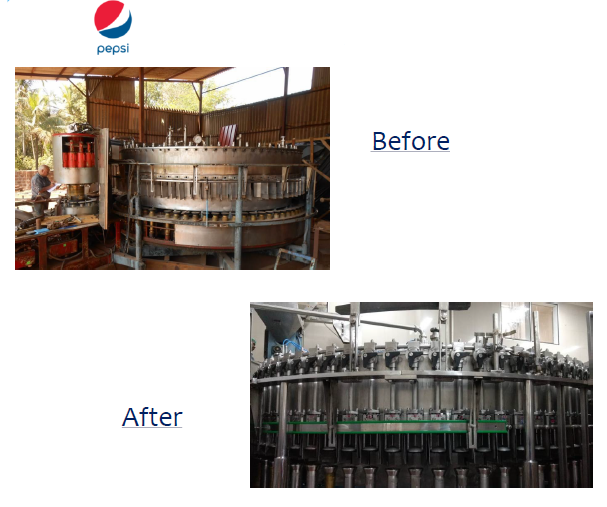

D) CSD GLASSS FILLER COMPLETE RE-CONDITIONING:-