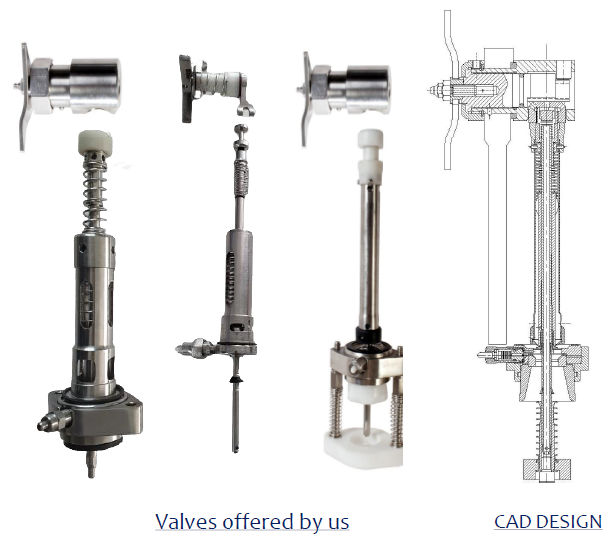

We are one of the leading design and manufacturer of all kinds of engineered filling valves to achieve optimum flow for new as well as existing machinery.

We offer 3 types of CSD (Carbonated) valves :-

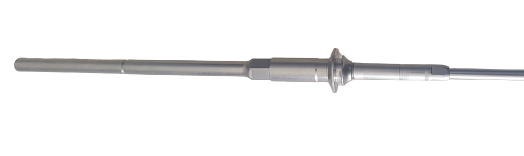

- Threaded vent tube design (Conventional Valve) :- Mostly used in glass filling machines.

Advantage :-

- Cost effective solution.

Drawback:-

In this design flow from the valve is less compared to other types of valves.

2)Collet Type design :-

- Mostly used in pet machines.

- Advantages:- Flow from this valve is better than conventional valves. With collet design, it’s better to do change over.

Drawback:- In this design slight change in centering assy can affect collet and results in bending of vent tubes and even stem thread damage.

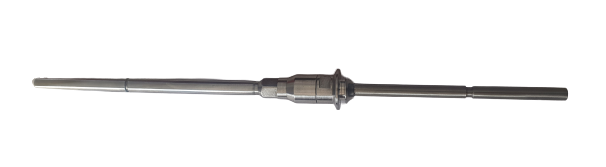

3)Push-type Valve :- Most efficient design out of all. In this vent tube and valve stem doesn’t have threading. Just by pushing vent tube into the stem we can do change over.

Advantage :-

i)This valve is high flow compared to conventional and collet type valve.

ii)Change over time is drastically reduced.

iii)Due to push type mechanism slight change in centering assy can absorb by the valve and as there is no threads involve in this valve stem never gets damaged.

We can modify any collet type valve of any manufacturer to push type design by changing valve stem and vent tube and keeping other parts same.

Check out our project where we successfully converted existing threaded and collet vent tube into push type vent tube at coca cola plants